OUR CAPABILITIES

Laser Cutting

Expanding To Server You Better

A Mazak Optiplex 4020 II is one of our fleet of specialty machines. This 2D machine can process materials ranging from the thinnest gage steel up to 1" thick mild steel with a workpiece weight capacity of up to 3,527 pounds. The machine features an expanded workspace to accommodate larger sheets up to 78 inches by 156 inches.

Highly-customized, made-to-order production projects are our specialty, and with the addition of this Mazak machine, we just upped our game.

What you need, when you need it. That's the Task way.

New Machine, Same Commitment

Staying Task Tough

While the addition of our Mazak machine means a change to our shop floor, one thing that won't change is our commitment to quality. At Task, that's a constant.

Our experienced and certified technicians comprise our one-of-a-kind team, and they're ready to take on your one-of-a-kind project. We can design and create the rare, made-to-order metal fabrication, machining, and fixturing products your business needs. Tough tasks are our specialty.

Fabrication and Welding Capabilities

We Like Heavy Metal

We’ll cut, bend, and assemble your one-of-a-kind metal products using our tried-and-true methods. From the first measurement to final assembly, we can construct any type of creation you can envision.

We own all of our specialty machines, helping us create masterpieces out of metal for you. This added value gives us the ability to complete your projects in one place at one time for the ultimate fit.

Our Fabrication And Welding Capabilities

CNC High Definition Plasma

Allows us to cut net shape parts within approximately 0.030”, suited to material thicknesses from .25”-1.25”.

Capacity: 1.25 “ x 72 “ x 144”

CNC Flame Cutting

A thermal process giving us the ability to cut very thick materials in the 1.5”-4” range.

Capacity: 4” x 72 “ x 144”

CNC Press Brake

Offers extensive bending capabilities to easily form your metal projects to any specification.

Capacity:12’ x 250 tons

Tube Bending

From square to round, we can easily bend tubes to whatever size you need.

Welding

We employ fully-trained welders in MIG, TIG, and PULSED MIG processes, and we guarantee work at the highest standards for aluminum, steel, and stainless steel products.

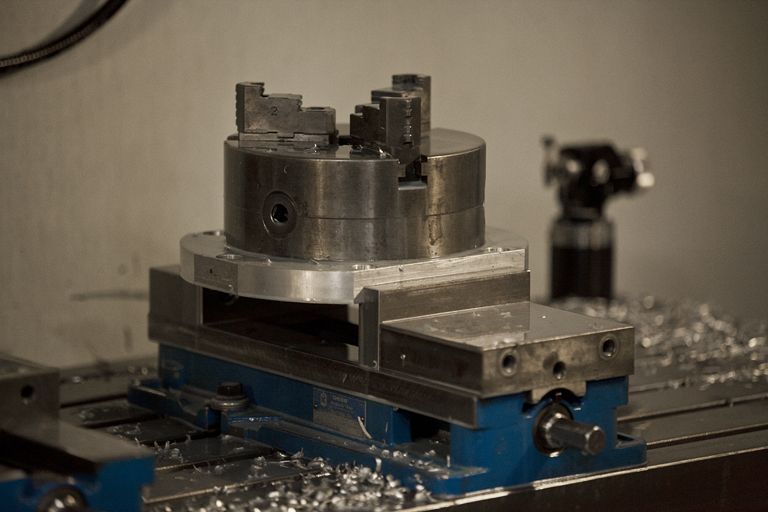

Machining

We'll Smooth Out The Rough Edges

We take a raw piece of metal and shape it to your needs with a variety of milling, turning, and sawing capabilities. Our CNC Machining options allow us to generate many products where size and complexity are not limiting factors.

If you have a project you can't figure out, that's where Task comes in. Our machines have transformed our production process, giving us the ability to develop specialty products at an even faster pace, which in turn saves you time and money.

Milling Capacity: 60” x 26” x 26”; 4 axis mills with probing for efficient accuracy

Turning Capacity: 18” diameter x 26” length; 4 axis lathe with live tooling

CNC Sawing: 16" x 20" bundle with programmable mitering.

Paint

We Have The Only Coat You'll Ever Need

From the initial color choices to the last stroke, Task Manufacturing is the expert at adding the finishing touches to your demanding projects.

We use an auto body-quality painting system, where we apply paint to your specifications, and we can professionally paint any product from industrial-quality to automotive finish suited to your needs.

Booth Capacity: 14’ wide x 10’ high x 30’ deep

Design

We Are Willing To Break The Mold

Our in-house capabilities, combined with years of practical knowledge, allow us to develop unique design solutions to fit your needs.

During the design process, we will always keep the manufacturing costs in mind to ensure quality products. We use the latest CAD Softwares- Pro Engineer and Solidworks.

Durable by design.